Main business activities

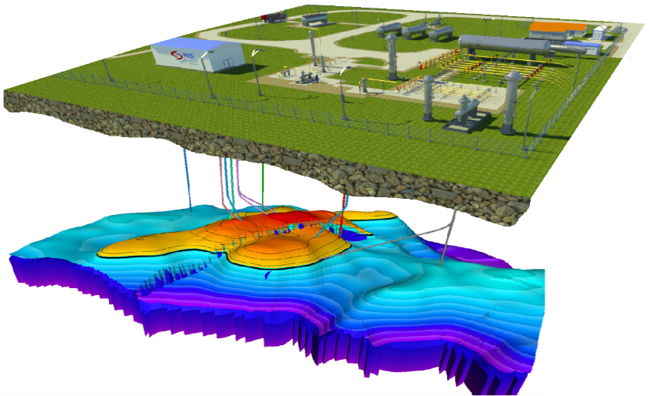

Integrated modelling of production precesses

Our team has extensive experience in Integrated Production Modelling (IPM), also known as Integrated Asset Modelling (IAM), covering the use of commercial software. The IPM takes into consideration the production of hydrocarbons from reservoirs via surface facilities, in a unique integrated model that includes the following: reservoir, wells, processing facilities and output pipelines.

In close collaboration with our clients, we design optimal development solutions, using IPSM to assess the impact of various results obtained from the reservoir and decisions on the development of underground parts in combination with options for ground facilities. This model reconciles a diverse set of technological inputs to estimate the impact of a particular decision on a project value.

Achieving a certain level of sophistication in system modelling can be crucial to predict accurately the performance. Combined with our cost estimation tools, we can prepare a full life cycle economic evaluation for a range of development options and achieve high quality decisions.

NTC has the expertise in using commercial IPSM software packages such as: Petroleum Experts (PetEx), (MBAL-Prosper-GAP, Resolve.), PipeSim etc.

Design and optimization of the artificial lift system

The method of choosing the appropriate system and design of artificial intelligence (AI) is done by looking at all aspects that are in production, which includes ground equipment, location, availability of power grid, underground equipment, reservoir characteristics, fluid types. The economic aspect also plays an important role in the return of investments and maintenance of the AI system.

Chemical support and engineering

Within our team, specialists cover well stimulation (treatment), the treatment of the area near the well during workover operations and EOR solutions.

Well stimulation is a well intervention using acids and solvents performed on an oil or gas well to increase production by improving the flow of hydrocarbons from the drainage area into the well channel. Before application in the field, we perform laboratory tests of acids, acid modifiers and solvent/acid mixtures, applicability and effects assessment, optimizing the design of acid composition in the sense of the type and concentration of additives.

Related laboratory tests performed in Upstream’s laboratory:

- General tests (density, viscosity, acid content, IFT, iron content, thermostability);

- Iron stability, corrosion activity;

- Compatibility with formation fluids;

- Coreflood experiments,

Over the last four years, as a part of the Well Stimulation project, our team has tested and optimized more than 10 acid formulations and five organic solvents, with recommendations for further testing.

Treatment of the area in the well zone during workover operations

During workover operations, the working suffocation fluid can affect the reservoir in a way that will reduce the production characteristics of the well. This may be due to excessive loss of killing fluid in the reservoir or swelling of clay minerals. In addition, during the production period, several processes may occur that will adversely affect the well, such as reservoir instability/the appearance of sand or the formation of organic or inorganic sediments.

For the case of excessive fluid loss – we perform tests on polymer gels for fluid loss, with or without a bridging agent, to determine the possibility of field application in the conditions present in reservoir. In different projects – six different fluid loss gels.

For the case of clay swelling – we perform the risk assessment through mineralogy and clay type analysis, testing and optimization of clay swelling inhibitors and additives, in order to preserve the permeability of the oil phase. In different projects, six different additives have been tested.

In the case of occurrence / deposition of sand – we perform an analysis of the deposits in the well, collected during the overhaul, analysis of the efficiency of the gravel pack, analysis of the deposits and recommend a suitable solvent. In addition, we performed an analysis and introduced into the company’s practice chemical methods for controlling the appearance of sand.

Related laboratory tests that are performed in the laboratory of Upstream:

- General testing of chemicals (density, viscosity, acid content, IFT, iron content, thermostability, compatibility);

- Compatibility with formation fluids;

- X-ray mineralogical tests, clay test;

- Linear swell gauge tests;

- Granulometric analysis;

- SARA analysis of organic deposits;

- Coreflood experiments.

Polymer and ASP EOR:

The goal of the method for improving production and oil recovery degree (EOR method) is to maximize oil production and recovery from the reservoir by reducing the water/oil mobility ratio (polymer injection) or by creating mobile oil-in-water emulsions by injecting ASP blend

We perform laboratory tests of alkalis, surfactants and polymers in order to optimize the design of the mixture for field testing. Tests include polymer testing and the optimization of concentration, the influence of the type of alkali and surfactants and concentration on the formation of micro-emulsion and its characteristics. Determination of adsorption / retention of used chemicals in reservoirs. The impact of blend on the oil preparation process.

Laboratory tests that are performed in the laboratory of Upstream:

For surfactants: Determination of HLB and CMC,

- For: formation, character and stability, thermostability of micro-emulsion,

- For polymer and ASP: all rheological tests.

- Compatibility with formation fluids;

- Coreflood experiments to determine additional assessment, oil production, resistance to compression and polymer retention.

References

- Our experts have expertise in the field of disassembly, inspection and failure analysis of SRP and ESP pumps.

- In the past four years, more than 5,000 projects have been carried out for different types of wells, and we have also created our own method for selecting the appropriate ALS based on well characteristics.

- With the diversity of artificial lift methods in the Balkan region, our team has gained great expertise in the design and optimization of SRP, ESP, PCP, gas lift methods and piston lift methods.

- We are proficient in using commercial ALS design and optimization software such as RodStar, SubPump, PCP C-FER.Wellflo etc.

- In the past four years: One project – polymer flooding of EOR, one project – injection of ASP.